The world of paper cups

By Steffen Andersen · 22. November 2019

In this blog post I will cover everything from how paper is made, to how it is turned into a paper cup and how they should be disposed of.

The blog post will also cover topics such as how and if paper cups are recyclable. In the end, I will share with you some of the upcoming ideas and trends within the paper cup industry. I will also be talking about the need for making more environmentally friendly products, and how you can get more environmentally friendly paper cups.

How are paper cups made?

How paper is made

Majority of the food, beverages, snacks are served in paper packaging, and it is clear that paper plays a key role in our daily life. Below I will run through the process of how trees become paper.

Making Pulp

After the trees are cut down, they are debarked and then they are made into wood chips and then through a mechanical process the logs are converted into pulp. The pulp is fed into the digester where they will be cooked in a chemical solution at a high temperature in a mix of sodium hydroxide and sodium sulfide.

Beating

This part of the process is where the remaining pulp is put through a pounding and squeezing process. During this step, various filler materials can be added such as chalks, clays, or chemicals such as titanium oxide which these additives will influence the opacity and other qualities of the final product.

Pulp to Paper

The pulp is laid and fed down on the mesh screening where the pulp is being squeezed by a series of rollers to help remove the water from it.

After the water is removed and the pulp is squeezed, the paper passes over a series of steam-heated cylinders to help remove the remaining water and after is dried, the paper is wound onto large reels. Paper is smoothed and compacted further by passing through metal rollers called calendars. The paper may be further finished by passing through a vat of sizing material to receive a coating, which can be brushed on or rolled on. This coating could for example be plastic for when making paper cups.

Types of paper used for paper cups

When making paper cups, the paper used for making them can have different kinds of certificates which can impact how much it cost, the environmental impact of it and the workers are impacted by it. In the following sections I will talk a bit about normal paper, FSC certified paper and FSI certified paper.

Cups from normal paper

The main raw material that paper cup manufacturers need is wood, which is a renewable resource. The paper used for normal cups can come from forestry all over the world, such as the Amazon, but it can also be forests in Europe that live up to standards of FSC, but do not have the certification. As explained above the tree then go through a process to become paper. When the paper is made, then some coating is added to cups so they can contain liquid – I will later explain the different kinds of coating that can be added to the paper.

Cups from FSC® paper

When a product or paper says it is FSC certified it means that the whole process of making this product has been FSC certified, so the manufacturer and all the distributors and vendors are FSC certified. Companies that wants to sell FSC products, they need to follow the rules and principles that FSC has established. The FSC organization has ten principles that the forestry needs to comply with such as that no more trees are harvested than the forest itself can manage to reproduce, thus securing a constant source of material.

In Europe, 92.2% of forests managed by European pulp and paper companies are certified either by FSC or the Programme for Endorsement of Forest Certification. In Europe, 72% of consumed paper is sent to be recycled and 90% of newspapers are printed on recycled paper.

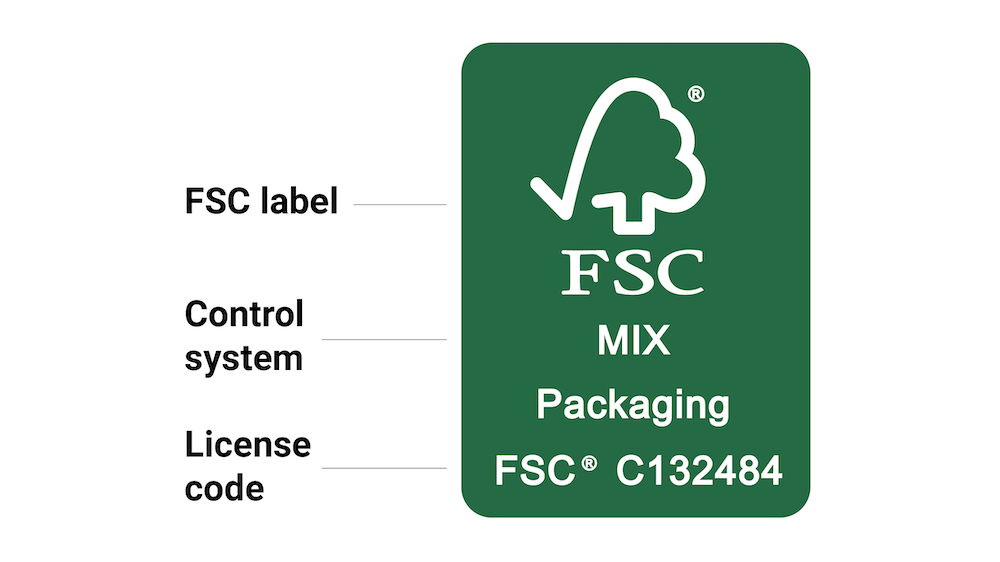

FSC has 3 different labels that are stamped on their products and they are called FSC 100%, FSC Recycled and FSC Mix.

FSC 100%

Means that the wood within the product comes entirely from FSC-certified and well managed forests.

FSC Recycled

Means all the wood or paper in the product comes from reclaimed or re-used material.

FSC Mix

This means that products that have this label on are made from a mixture of recycled materials, FSC-certified forests or controlled wood.

There is a lot of interesting facts about this organization and all around their industry. If you think you are missing out on what is going around the world with our environment, it is recommended to read through our article about FSC-Certification. It will give you a slight glimpse of what they are doing so everyone can enjoy a healthier environment.

We are FSC certified under FSC® C132484, SCS-COC-005763-BC.

FSI Paper

FSI stands for Fibre Sorting, Inc., they have been in the paper making industry for more than 27 years and they are producing paper products purely from recycled materials. FSI uses 100% recycled paper as raw materials, to ensure a steady and reliable supply of raw materials, the company works together with waste paper dealers and suppliers in the Philippines. In Limepack we do not know anyone who offers paper cups made of FSI paper.

How are cups made from paper?

After the production of paper is finished, the paper is transported to facilities and industries for different purposes, one of them is making paper cups.

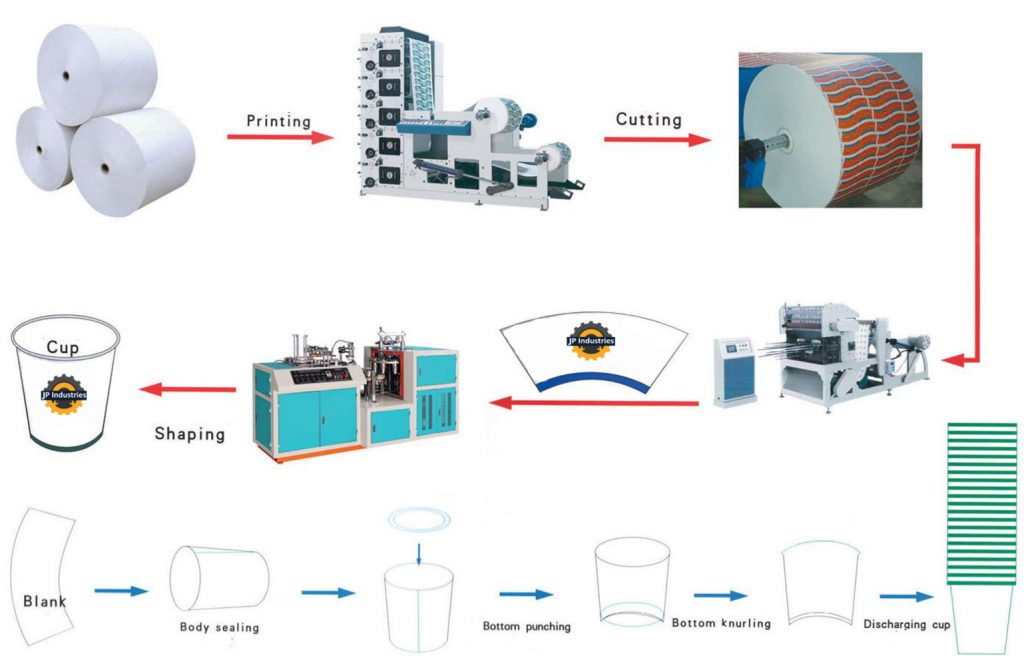

The paper cups can either have three or four stages when they are made – The number of stages depends on if they are printed or not, if they are printed they are printed before being cut out and folded into paper cups. This is also the reason why it is also almost impossible to print on already folded paper cups.

When the paper cups have been printed, they are cut out in bended templates hereafter they go in to a big machinery that folds the paper cups and bends the top of the cup so they are pleasant taking a sip of. In the last step the bottom of the paper cups are put in and reenhanced to make the structure of the cup strong.To have a better and clear picture of how paper cups are made you can check out this video.

Printing on paper cups

Many paper cups are also used for marketing purposes, and therefore they are printed with the logo of the coffee shop or the company that uses them. There are different printing methods and each method is specialized in different ways to make the printing more efficient and useful to the customers.

Offset print

Offset printing is one of the most used printing methods for paper cups and especially when printing larger quantities.The more expensive part about offset, is the printing plate. The printing process ensures that the print is the same on the first cup and cup number one million. The effective process also ensures good prices, and prices that will get lower the higher amount.

Tampon print

Tampon printing is similar to ’stamping’ process where the ink is taken from an etched metal plate and placed onto a flexible pad and later stamped onto the article to be printed. Tampon printing is known also as pad printing and is made from silicone and can adapt to any uneven surfaces.

Flexo printing

Flexographic printing is the new modern version of letterpress and it can be used for printing on almost any type of substrate, including paper, plastic, metal and cellophane. The pros of of flexo printing are that can run at extremely high press seeds and prints on a wide variety of substrate materials, but the cons are that the cost of the printing plates are very high but if they are properly cared for, they can last for millions of impressions, also if there is a need for a complex job, it can take up to several hours to set up the printing.

Digital print

One of the most common and efficient methods of printing color pictures or documents onto paper or another material is digital printing and to most people is most commonly known as ‘’printing’’.

Digital printing is used more about newspapers because it is faster and cheaper when it comes to printing articles that needs a lot of different design in smaller quantities. This is because of the low cost for printing plates.

CMYK and Pantone colors – the differences

CMYK and Pantone colors are the most used color combinations, and they each have some unique factors that make them good for different situations. In this section we will cover the most important details between CMYK and Pantone colors. This will give you a better understanding on the color process and which one is more preferable for each situation.

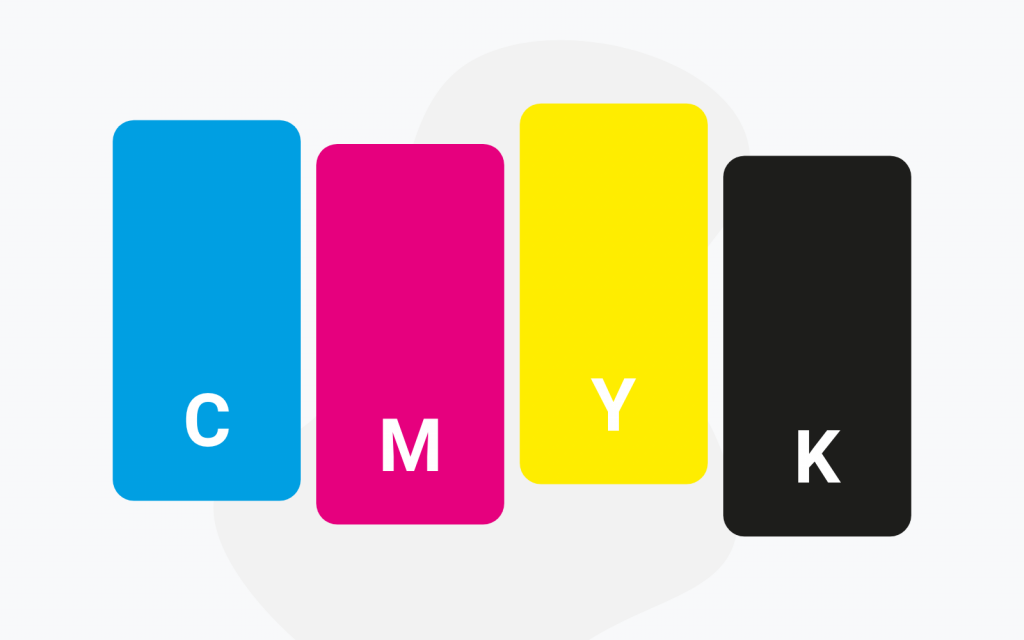

CMYK

CMYK is a better solution if the printing job doesn’t require a high quality colour and the other reason is that it is a more reasonable price than Pantone. A printing plate is created for each printing ink before the process is started, 4 plates of 4 colours is created which is C-M-Y-K. Because there are 4 plates of 4 colours is created, it is possible to use as many colours in the same design as you prefer without having to pay any additional cost.

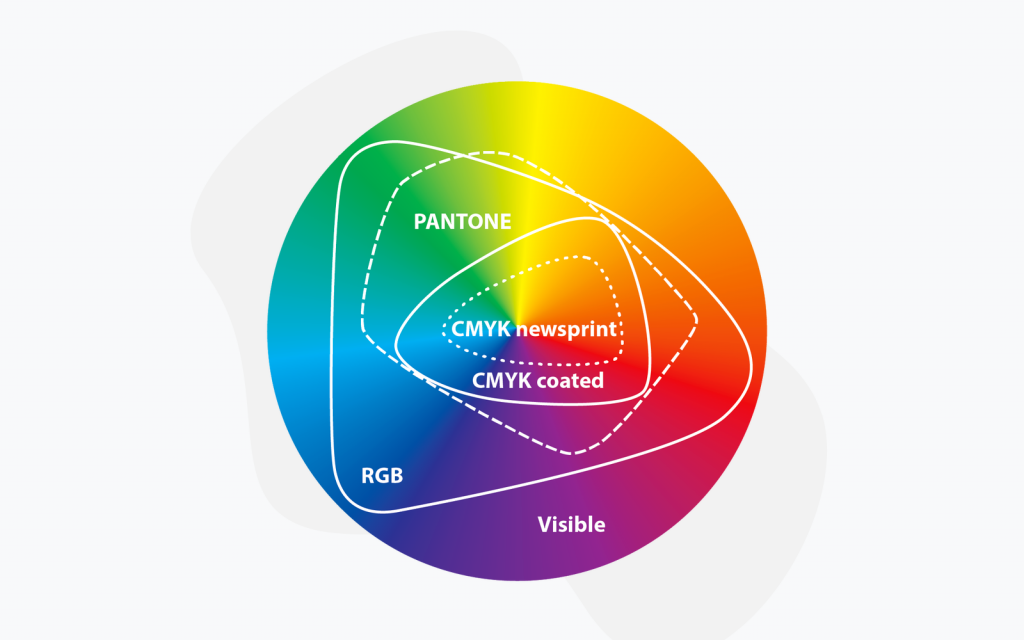

CMYK colors are almost only used to print on paper due to less precise coloring. CMYK colors is a lot easier to bundle with other designs which makes it cheaper to use in smaller quantities. CMYK has a limitation when it comes to produce the same vibrancy that can be achieved with Pantone.

Pantone colors

The other process which is Pantone, is more efficient and a better choice to print unique colors. Pantone is able to produce more colors closer in shade to the ones seen in digital design stage. Pantone is more suitable when it comes to branding and logos because the colors are more precise and matching to the original design. Pantone boasts a total of over 1,800 different colors and they are created with thirteen base pigments that create a variety of unique colors. The problem regarding Pantone colors is that you have to pay an additional cost for each extra color that you would like to add into your design. Pantone colors can be used to print on everything, since it has such a precise color.

Coating for paper cups

As I have explained earlier, when making paper cups there is put a layer of coating on them inside, so it can contain liquids and other drinks. The coating can be made of different kinds of plastic and some can actually be made without plastic coating. I will in the following sections be talking a bit about the kinds of coating and what it means for the recycling of paper cups.

Paper cups with PE – plastic coating

First and foremost, the majority of paper cups are covered with a thin layer of plastic inside the cup which holds the cup together and prevents the cup from leaking. The plastic coated paper cups are coated with PE-plastic, which mean that the plastic is made of naphtha which is an extra of oil which means the plastic coating is made from a limited natural resource. The plastic coating is of course food safe and can come in contact with food materials. The plastic coating is the reason why most paper cups cannot be recycled.

Paper cups with PLA – Bioplastic

Like every other paper cup there is made, also PLA paper cups has a thin layer of plastic inside the cup but that is a different one than the others. PLA plastic is made from plant based materials such as sugar, corn starch, cassava, sugar cane or sugar beet.

Corn plants are milled to extract the starch, in the room of glucose. The glucose is then fermented to produce lactic acid. A chemical process transforms the lactic acid to a polymer, which can be made into pellets, known in the industry as resin.

PLA has a low melt point, so is best for cold drinks that is no hotter than around 40 degrees celsius. Where more heat resistance is needed, such as in cutlery, or lids for coffee. This involves adding chalk to the PLA to act as a catalyst, and then rapidly heating and cooling the PLA resin during production. For PLA products to be composted takes 3-6 months in industrial composting system facility. Production of PLA uses 68% less fossil fuel resources than traditional plastics and it is the world’s first greenhouse gas neutral polymer.

Plastic free paper cups

As we have mentioned earlier, now they have made it possible to use paper cups that are not coated with plastic. This project was set to production in 2017 and the tryout of the paper cups was successful. This section below will cover how they made it possible and give you insight what benefits they offer.

So basically, all the pressure made from the public about plastic waste and paper cups that weren’t recycled, governments, businesses, manufacturers had to move fast and to come up with a perfect idea how to reduce plastic waste. This ended up resulting in an idea of plastic-free cups, which now is reality.

The reason why this hasn’t been introduced before was because it was not able to make paper contain liquids without the plastic layer. That is why many people find it interesting how these plastic free papers are able to contain liquid, which I will cover shortly below. I have also made an in depth blogpost about plastic free paper cups.

The coating that makes it possible to contain liquids is created with water-based dispersion on both sides of the layer, while the middle layer of the cup is made with chemi-thermomechanical pulp.

Later down below you will find out about how they are recycled and what is the process of them after being used.

How are paper cups transported?

Transport is a very important factor during the process of finalizing the order. As we know that CO2 emissions which is released during the transport impacts our environment. The section below will explain the types of transport normally used for paper cups and the amount of CO2 released during each one of them.

After the paper cups are manufactured and finished with production, they pack them and make it ready to transport the goods to the delivery point. Nowadays, globalization makes it easy to send goods around the world and much faster than it was before. Most of the transportations are being made by airplane, truck, train and ship.

The effect of CO2 emissions of airplanes are 2 to 3 times higher compared to the emission of the transportation forms on the ground, because airplanes release the CO2 in high altitudes into the atmosphere, where they can do much more harm.

You can below see the amount of co2 spent from the different kinds of transportation, it will be shown in grams per metric ton of freight and per km of transportation.

Airplane (average cargo B747) – 500g Lorry or Truck – 60g to 150g Train – 30g to 100g Ship – 10g to 40g

To calculate the emission gas from a truck you have to take the amount of distance the truck has traveled, the weight or amount of shipment and the mode’s specific emissions factor. For a truck that travels 1,000 miles with 20 short tons of cargo. Multiplying 1,000 miles times 20 tons which will give us 20,000 ton-miles. Afterwards adding the emission factor for a freight truck which the average in the US emits 161.8 grams of CO2 per ton-mile. The next step is multiplying the emission factor with the total ton-miles (161.9 X 20,000) which totals the amount of 3,236,000 grams of CO2 and we convert that amount to metric tons which is a standard measurement unit for emissions of greenhouse gases and that gives us 3.24 metric tons of CO2 for this one move. We take the amount of grams of CO2 and divide it by 1,000,000 because that’s the amount of grams in a metric ton.

So based on the numbers and information mentioned above, we can approximately calculate the difference of an airplane and a truck and see who releases more CO2 and has more impact on the environment.

- Airplane for 330 miles, releases 33 tonnes of CO2

- Truck for 1000 miles, releases 3.5 tonnes of CO2

We would have to send 10 trucks and all of them to cover 1000 miles each, and that will make the same amount of CO2 released as a plane that travels only 330 miles. A truck travels 3 times more than an airplane and still releases the 10% of the amount that an airplane does.

What can paper cups be used for?

This section is to give you an idea of what paper cups can be used for and some ideas for where to go cups can be found elsewhere than coffee shops.

Nowadays, paper cups can be found in the majority of fast food restaurants, coffee shops and local grocery stores. The reason why local grocery stores are selling paper cups is for the customers who are planning a trip someplace, a picnics with friends or family, home parties, and etc.

Paper cups have made it easy for customers to be able enjoy a coffee on the way to work or if they are in a hurry.

Other than being used in coffee shops and fast-food restaurant, paper cups have become a huge part of festivals, family festivities, corporate events, cocktail events, seminars and many more celebrations. Paper cups are also very commonly used in offices, schools, hospitals.

Paper cups are also more and more often used by companies, and the primary reason why paper cups have become so popular in corporate events is because they are easily customisable, so the company can print their brand or message on the cost without having to pay a lot extra.

How are paper cups decomposed?

This section below will be introducing you what happens to paper cups after they are being used and the differences between PLA and normal paper cups and plastic-free cups on how they are recycled or composted.

Plastic-free cups

As we mentioned above in the section about how plastic-free paper cups are made, we will talk about how they can decompose. They can either be recycled with full fiber recovery and used in the production of new paper products, such as magazines or paper bags. Recycling will be reducing the carbon footprint of a paper cup by half.

If you throw them in paperboard bins or recycling bins, they will be collected and sent to one some of the largest paper mills in Europe so they can be recycled. Since the plastic-free cups are made with virgin wood fibers it will be valuable as a raw material to the paper mills because it will be useful as a potential source for the production of magazine papers.

Other than being recycled in the paper mills, plastic-free cups can be degraded in nature with a specific required conditions, such as the right temperature. Being plastic-free enables the products to be easily thrown in normal paper and board recycling bins where they will be collected and sent to recycling manufacturing.

If the cup is without plastic layer it makes it more easy to recycle it and renew it to other paper products, such as paper bags.

PLA Paper cups

Biodegradable paper cups are made with a thin layer of plant-based plastic (PLA), as explained above. The PLA plastic and the biodegradability does actually mean industrial degradable since the PLA plastic cannot be decomposed in nature.

The plastic can be decomposed under certain conditions in the industrial facilities, since it has to be moist room at a certain temperature for around 90 days before it is decomposed. The PLA plastic should by principle be faster to degrade in nature, but it has not been well documented and it is therefore not a fact.

There are not many countries in the EU who has these industrial facilities to our knowledge the only countries who has these facilities is the UK. The PLA plastic cups should therefore be thrown out like normal paper cups, so they can be burned and turned into biomass.

Normal Paper cups

The plastic material which is used to make the cup durable for liquids makes the paper cups non recyclable in nature and it takes hundreds of years to break down and when the cups gradually breakdown they end up in tiny microplastics.

In recent years, the matter of plastic waste which includes also polyethylene-lined disposable coffee cups has been raised when a report from the UK came in that showed, around 2.5 billion coffee cups were thrown away each year and that number is likely to be even higher now. In the UK there are currently a few specialist plants that are able to process the disposable used cups, and in the end as a result more than 99.75% of the cups don’t get recycled.

What then happens to the paper cups if they are not recycled? In most countries the paper cups ends up being burned for energy along with other thrash and especially food thrash. It can therefore be categorized as biomass which is a sort of energy-source especially used in northern Europe and the UK. It is therefore important that you throw out your paper cups with the normal trash, so they end up in the right facilities so they still contribute with energy after they have been used.

What new innovations are being made around paper cups

There is a lot of attention on how to make paper cups more environmentally friendly. This section below will cover most a lot of the ideas surrounding paper cups and how they or factors impacting them can be made more sustainable.

Improving recycling system

The problem of paper cups not being recycled is because the plastic coating clogs up the filters at the paper mills. The UK went from having one small paper recycling plant, they have opened two more and they are building the biggest paper recycle lines at their facilities. In the meantime, coffee shops have taken the responsibility upon themselves to finance coffee cup bins where the customers can throw their cups after being used, so it is easier to separate the paper cups from normal thrash and made it easy for the recycling plants to collect the thrash. These recycling efforts have estimated that there will be 100 million paper cups recycled in 2018.

What are coffee chains doing?

A 1 million pound fund was created by Starbucks and environmental charity Hubbub reason was to reduce the waste of paper cups, to reach the goal they will invest the money to help expand and improve paper cup recycling facilities across the UK and other countries.

The fund that was initiated was financed by the 5p paper cup charge or ‘’latte levy’’ which was introduced a year before in an effort to reduce the overuse and waste of an estimated 2.5 billion disposable cups every year.

To help minimize the waste of the paper cups, biggest coffee shops in the UK such as Pret a Manger, Costa Coffee, Starbucks, Greggs and Café Nero are offering discounts for people who will bring their own cup to have the coffee instead of using a disposable cup.

CO2 neutral paper cups

When we are saying paper cups have a major impact on our environment, we also include the CO2 they emit while they are produced, transported and decomposed. This section will talk about how it is possible to make paper cups CO2 neutral.

It is unfortunately not possible to produce and transport paper cups where they do not emit more CO2, why you need to do other activities for the paper cups to become CO2 neutral. The kind of activities these organization/companies do can be planting more trees, helping people with isolating their houses so they use less energy or a third option that is CO2 positive. We do not do these activities our self, but we work with an organization who help villages on the African continent with isolating the houses. We work with another organization about this, because they are better at spending the money as effective as possible.

The organization then calculates how much CO2 is emitted by producing a 1000 paper cups, and then they will charge us how much it will cost to make activities so the paper cups become CO2 neutral. We will then add this extra cost of making them co2 neutral to the standard price of paper cups, and we will then send the money to the organization who will then do the CO2 neutral activities.

Natural grown biodegradable coffee cups

An innovative design company is trying to minimize the plastic waste by ‘growing’ the coffee cups from a fruit.

They are made from gourds, which is a similar fruit to pumpkin, and they are ‘grown’ inside and forming the perfect shape of a coffee cup. The idea comes from fast-growing squashes which they were used by our ancestors for holding liquids and drinking water. Everything about this cups is completely organic.

To make different sizes they 3D-print molds and put them inside the baby gourds and let them grow, and after they are mature you take it off and let the gourds dry. It takes three weeks for gourds to fruit from that day when is planted, and then it takes four months where they need to be outside and dry before they can be used.